Heat Exchanger Tube Plugs

Use our Plug Selector to find the right solution for your leaking heat exchangers and place a request for quote.

Click Here for Plug SelectorTube Plugging Products

- High Pressure Tube Plugs (up to 7,000 psi)

- Low Pressure Tube Plugs (up to 250 psi)

- Tapered Tube Plugs

- Accessory Tools

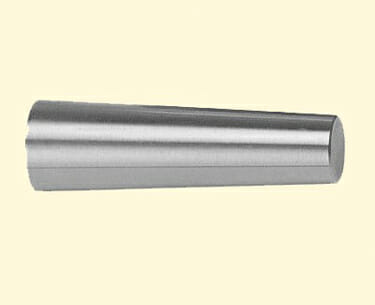

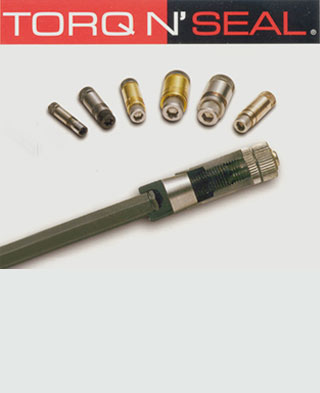

Torq N’ Seal® tube plugs for heat exchangers are the ideal solution for your upcoming turnaround or maintenance project. They create a permanent, positive seal greater than 7,000 psi (tested to 10,000 psi!!!) with the simplest installation procedure on the market. Use Torq N’ Seal® and you can be confident your heat exchanger maintenance or repair project will get done on time and under budget.

In addition to our high pressure Signature plugs, we offer a range of Condenser / Low Pressure plugs. The Elastomer Condenser Plug in particular is a simple and cost-effective solution when temperatures are below 350 deg F and pressures are below 250 psi. Install these plugs easily by using the Specialized Hex Capture Drive provided with each purchase. The result is that you can reduce turnaround time significantly on condenser plugging projects without sacrificing on quality.

Even if our stock items don’t fit your needs, our ISO:9001 certified machine shop has the expertise and manpower to quickly design and make custom solutions. There is always a Torq N’ Seal® plug that’s right for you, regardless of your particular application. Contact us now to speak with one of our engineers about heat exchanger tube plugs. They will help you identify the correct plug and answer any questions you may have about installation or efficacy.

You can also use our Plug Selector to help narrow down your search. Simply click the most relevant option at each step and you will get a part number and can even submit a quote request directly from there. Torq N’ Seal® has been successfully serving the power, oil & gas, chemical, and other industrial markets since 1982. We simply offer a better solution to heat exchanger maintenance / tube plugging projects.

We encourage you to try our heat exchanger tube plugs today!

Phone: 201-641-2130 Email: SALES@TORQ-N-SEAL.COM

Heat Exchanger Tube Plugging Articles

A Better Way to Plug Fin Fan Exchangers

Fin Fan Exchangers are now commonplace in refineries and power generation facilities due to favorable O&M costs, water limitations, and groundwater concerns. The tube plugging of these units is thus a critical piece of any refinery or power plant turnaround. Torq N’ Seal® Heat Exchanger Tube Plugs provide a fast, simple, and effective solution to this growing need.

Read More

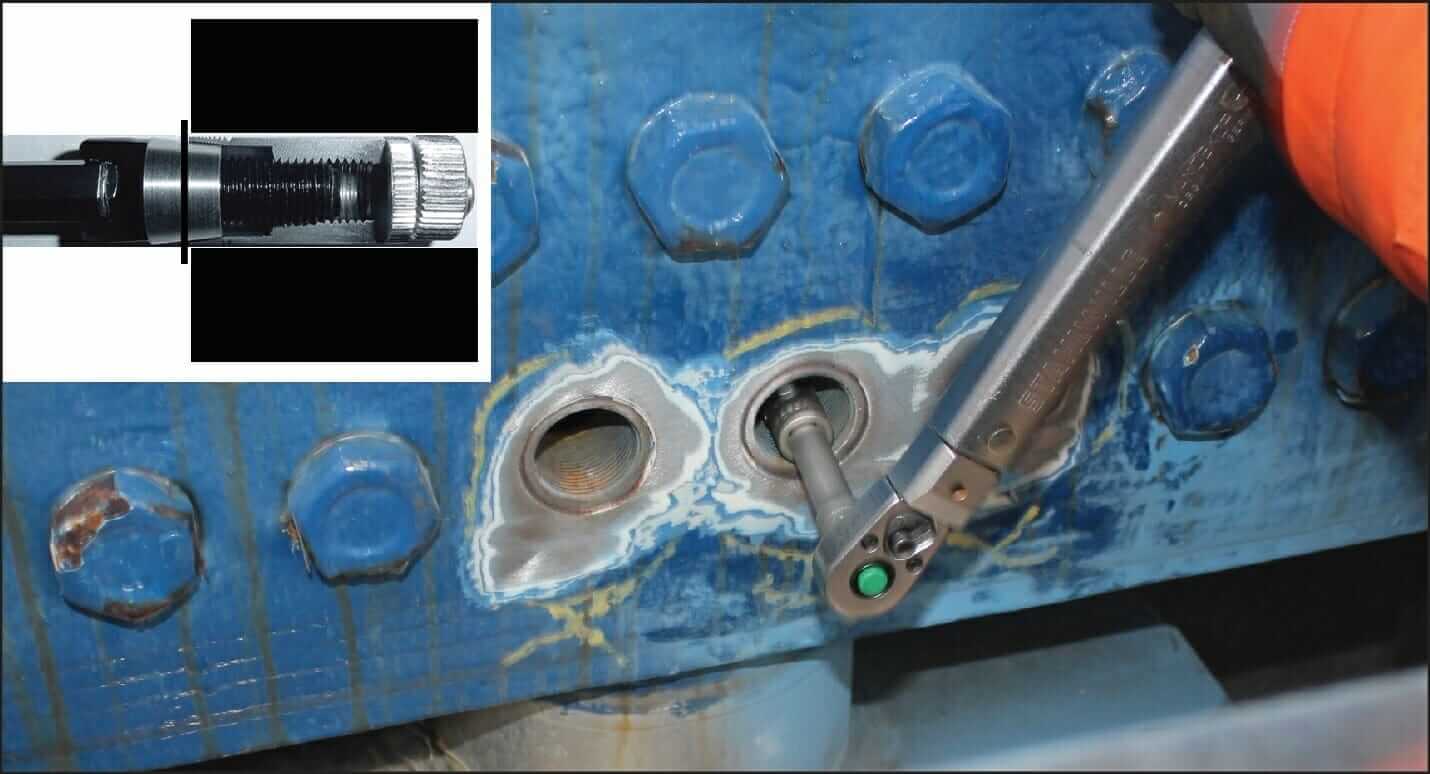

Tube Plugging: How to Plug A Leaking Heat Exchanger Tube

Heat exchanger tube plugs are used to seal leaking heat exchanger tubes, thus preventing damage to adjacent tubes, and keeping the efficiency on an aging exchanger as high as possible. Torq N’ Seal® Heat Exchanger Tube Plugs offer a fast, simple, and effective way to seal leaking heat exchangers up to 7,000 psi.

Read More

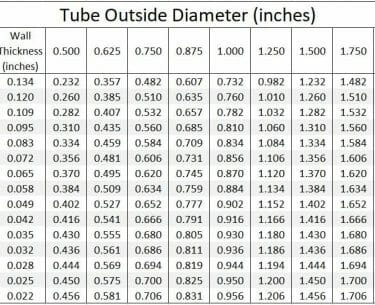

How to Select the Correct Heat Exchanger Tube Plug

Torq N’ Seal® Heat Exchanger Tube Plugs provide a fast, simple, and effective solution to inevitable tube leaks. Understanding all the considerations ahead of time and having the correct heat exchanger tube plugs on hand makes all the difference in a successful maintenance plan.

Read More

Heat Exchanger Tube Plugs for Fin Fan Exchangers at Oil Refineries

Torq N’ Seal® Heat Exchanger Plugs comes to the rescue with a step design that plugs the tubesheet hole directly while also providing a support structure for the remaining tube still in place. Thus, the oil refinery customer was able to both seal and secure their leaking tube without having to perform any additional work, getting them back online quickly and safely, on time and under budget.

Read More